News and informations

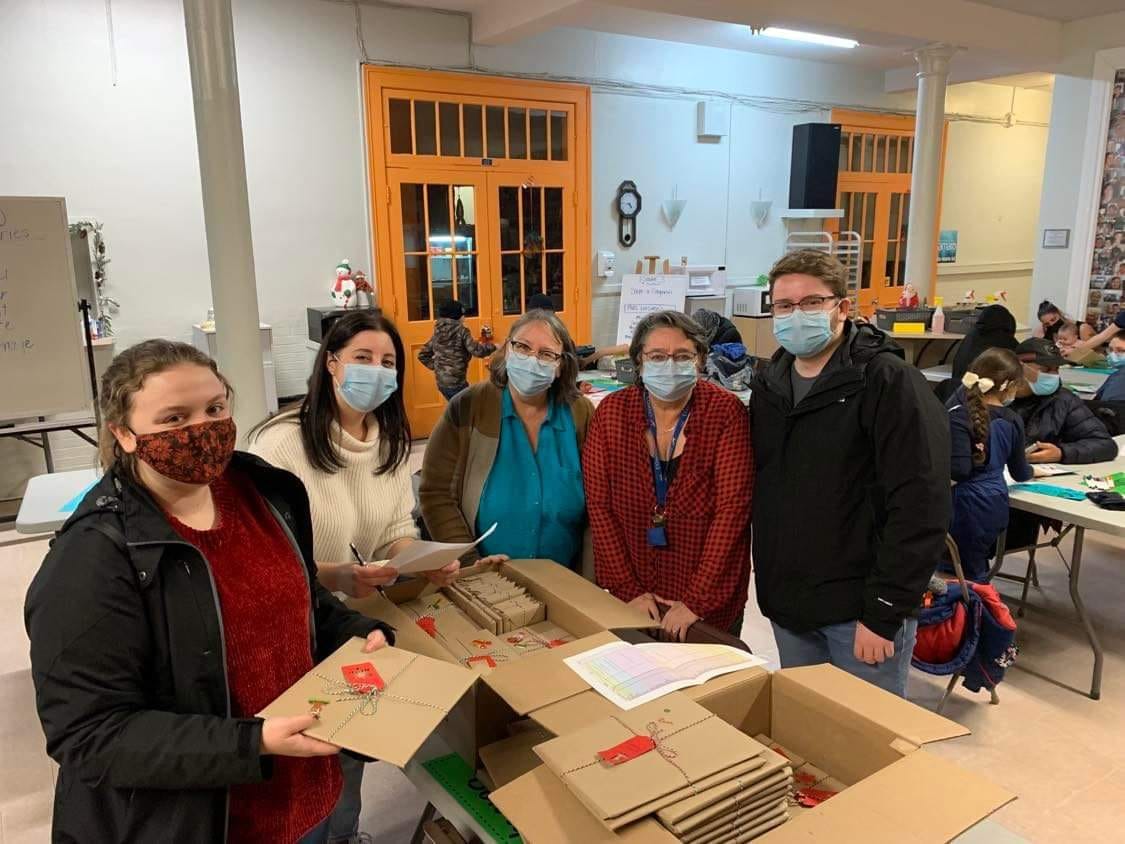

Tis’ the Season… of Giving

Giving of time, money and goods is a notion that is emphasized even more during the holiday season at Groupe Somavrac. To encourage this dedication

The battery industry: an important market for Groupe Somavrac

From an interview with Mikael Gagnon, Business Development Manager since 2017 Groupe Somavrac is composed of a team of professionals offering services that meet you

Discover our Bécancour Terminal

Excerpted from an interview with Louis-Philippe Gravel, Assistant Director of Operations for Servitank since 2020. Halfway between Quebec City and Montreal lies the Servitank terminal

What Sets Groupe Somavrac and its Transportation of Hazardous Materials Apart

Excerpted from an interview with Martin Deschamps, Transportation Director for Transport Somavrac and Transport Servitank since 2017, and Alex Gagnon, Assistant Director of Transportation In

Discover Servichem

Excerpted from an interview with William-Olivier Masson, Director of Operations for Servichem and Chloretec since February 2020 Get to know Servichem in this article. Servichem

Three Distinctive Features of the Bécancour Terminal

Excerpted from an interview with Louis-Philippe Gravel, Assistant Director of Operations for Servitank since 2020. Servitank offers complete, efficient solutions for the handling and warehousing

4 Reasons to Choose Groupe Somavrac and Its Handling and Transformation Service

Groupe Somavrac specializes in five distinct services to provide customers with turnkey end-to-end logistics solutions. Product handling and transformation are two of these services. Discover

ENVIRONMENT WEEK AT GROUPE SOMAVRAC

As part of Environment Week at Groupe Somavrac, which took place from April 19 to 23, 2021, several activities were held to raise employee awareness

5 reasons to choose Groupe Somavrac ans its stevedoring service

Groupe Somavrac’s supply chain and logistics expertise is what sets the company apart and enables it to provide a full range of services. In this